In Spring 2021, our two Tunnel Boring Machines (TBM), Florence and Cecilia began their 10-mile journey under the Chiltern Hills. This is the launch of TBM Florence from the South Portal.

Segments that line the Chiltern Tunnel were produced on site at the South Portal in temporary pre-cast factories. Each segment weighed up to 8 tones. 112,000 segments were needed to build the Chiltern Tunnel.

In February 2024, TBM Florence completed her 10-mile journey under the Chiltern Hills. Colleagues from Align, HS2 and our Supply Chain were there to witness the moment she broke through at the North Portal.

Members of the Align Tunnelling team celebrating the safe arrival of our second TBM Cecilia in March 2024 having also completed her 10-mile journey under the Chiltern Hills.

We have constructed 38 cross passages linking the northbound and southbound tunnels.

Work began on the South Porous Portal in early 2023 and was completed in Spring 2025. Designed to eliminate the possibility of a ‘sonic boom’ being created by high-speed trains entering/exiting the Chiltern Tunnel at 200mph, two perforated concrete hoods cover the track, extending the 10-mile long tunnel into the open air.

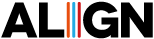

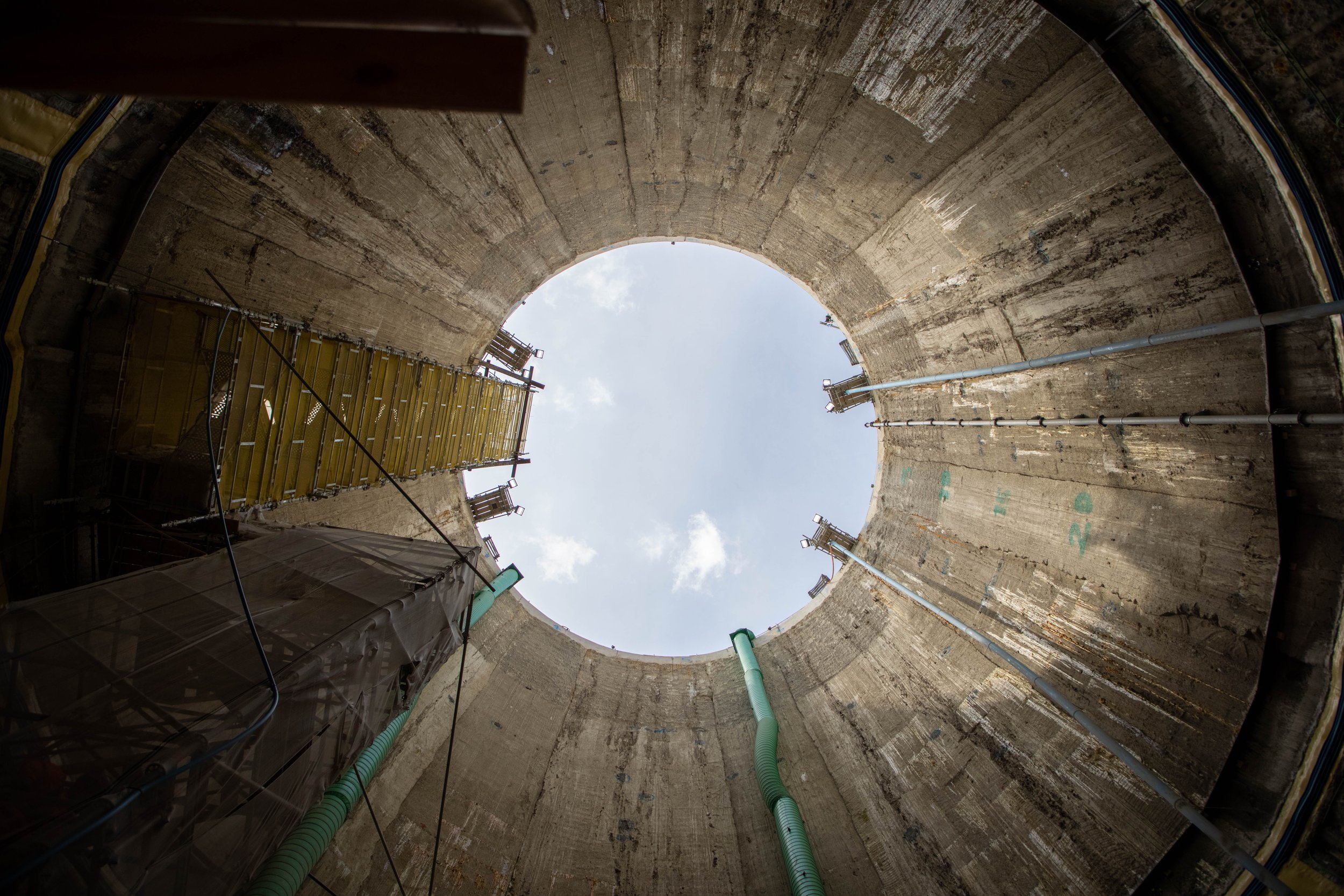

A peek inside the Chiltern Tunnel.

In August 2025 we completed construction of the 10-mile Chiltern Tunnel, the longest tunnel on the HS2 route, the South Portal porous portal structures and the accompanying earthworks trace.

We have five Shaft sites along the Chiltern Tunnel route for ventilation and access. This is a view from the bottom of the Amersham shaft in July 2022 during construction.

A view of the Chalfont St Giles shaft headhouse in June 2025. The headhouses were designed in consultation with local communities, our priority has been to blend the buildings into their surrounding landscape, taking inspiration from the style of local barns and other agricultural buildings.

The earthworks team started work back in 2019, to date approximately 9 million cubic metres of earth has been moved so far (August 2025).

The Colne Valley Western Slopes project, will see 127 hectares of former agricultural land restored to biologically diverse grassland, reminiscent of the rare chalk downlands that are found in pockets across the Chiltern Hills. The newly landscaped area is being seeded with a variety of plants that thrive in chalky soils.

In May 2022, we launched ‘Dominque’ the Launching Girder which installed the 1,000 deck segments for the 2.1- mile Colne Valley Viaduct.

The mammoth temporary 100m long viaduct precast factory with a volume of 105,000 cubic metres was larger than the Royal Albert Hall. Dismantled in early 2025 to be reused on another UK major project

Viaduct deck segments were made using a ‘match-casting’ technique – where each segment was poured against the previous one, ensuring the whole deck fitted perfectly when assembled on the piers.

In early September 2024, the final deck segment of the 2.1–mile (3.4km) Colne Valley Viaduct was installed. The team gathered to celebrate this historic moment as the Colne Valley Viaduct is now the longest rail bridge in Britain breaking the record held by the 2.2km Tay Bridge linking Fife and Dundee since 1887.

The Colne Valley Viaduct is the longest railway bridge in the UK. Recognised for its sweeping curve across land and water. It will carry trains running to and from the capital at speeds of up to 200mph/h (320km).

The bridge design, inspired by a stone skipping across the water, features elegant spans up to 80 meters long, blending beautifully into the landscape.

Colne Valley Viaduct Finishes works began in 2023 and included installation of the robust kerb with over 3,600m3 of concrete poured, the installation of 1514 parapets, the high-performance waterproofing membrane protected by a 100mm thick steel fibre reinforced slab, 41,000 troughs placed by mechanical means and lids placed by hand! As well as the 4m high noise barriers on each side of the viaduct, internal drainage system and structural health monitoring systems.

In August 2025 we completed construction of the Colne Valley Viaduct, the UK’s longest railway viaduct at 2.1 miles (3.4km) long!